Inquiry

Inquiry

In order to get connection force on a thin plate,

taps are made by burning or bolt and nuts are used by welding.

However, it is difficult to get the desired connection force.

n such a situation, clinching fastener is the best product that can secure

screw thread on a thin base material.

Clinching fastener products are designed to to endure rotation resistance

with saw-toothed bumps formed on the products.

In order to get connection force on a thin plate, taps are made by burning or bolt and nuts are used by welding. However, it is difficult to get the desired connection force. In such a situation, clinching fastener is the best product that can secure screw thread on a thin base material.

Clinching fastener products are designed to to endure rotation resistance with saw-toothed bumps formed on the products.

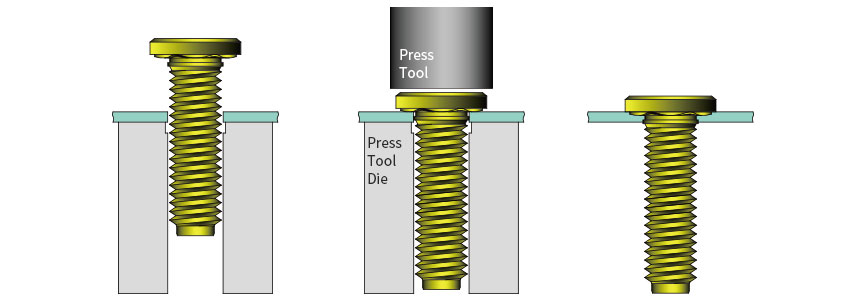

1) Put the base material on the die and insert STUD bolt into the hole.

2) Press in the head portion of STUD bolt using the press machine.

3) Connection is completed when the platform of the STUD bolt is completely pressed into the base material.

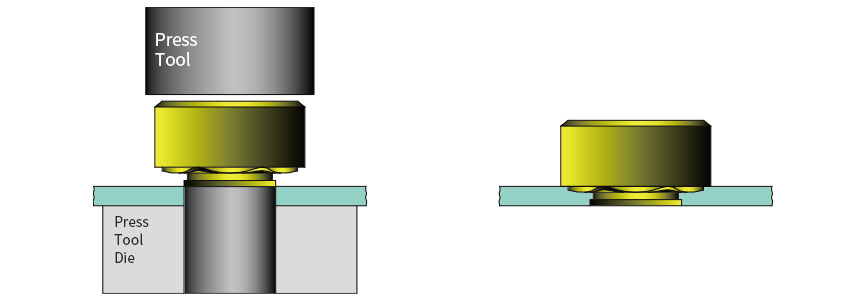

1) Put the base material on the die and insert clinching nut into the hole.

2) Press in the body part of clinching nut using the press machine.

3) Connection is completed when the platform of the clinching nut is completely pressed into the base material.

No thermal deformation due to welding and straightness can be maintained.

Easy working and no need for skilled workers.

Very high rotation resistance torque

Nice outer appearance without bumps on the surface of the base material

Quality inspection can be done with the naked eye.

Can be used with simple press machine.

Boiler industry

Automobile industry

Computer industry

Living hygiene industry

Small medical devices

Home appliance